My conversion from tailwheel to tri-gear

Scroll down to the conversion status Updated July 2, 2018

On June 28, 2017 after 19 years and over 1,000 hours of flying my Mustang II I decided to go ahead with the plan to convert mine from a tailwheel to tricycle gear configuration.

The most common question is: "Why?"

My answer is that I wish to have my sons and eventually my grandchildren fly the plane and we determined that for them to easily, comfortably and safely fly the Mustang II a tri-gear would be better for them.

(There have been numerous discussions about tailwheel vs. tricycle gear, but I don't wish to go into that here.)

Major Tasks

- Determine if an alternate engine oil sump is available that could accept a fuel injector from the front.

(My IO-320-B1A engine has a rear-mounted fuel injector which would interfere with a nose gear assembly.) - Complete

- Purchase nose gear assembly - Complete

- Determine if I could have adequate prop clearance with my 72" Hartzell constant speed prop - Complete

- Engine mount modification

- Install nose gear assembly

- Purchase or make tri-gear torque tubes and gear legs

- Modify / rebuild cowling

- Install new main gear torque tubes and gear legs

Additional Tasks

- Put aircraft in jig to remove gear

- Preserve ('pickle') engine

- Remove main gear

- Match drill new torque tube attach brackets

- Purchase TIG equipment, learn TIG welding

- Heat treat welded engine mount and gear assemblies

- Sheet metal work under center section

- Modify engine with new sump for a forward-mounted fuel injector

- Air intake / filter

- Move alternate air box and control

- Move or install new throttle and mixture controls

- Modify or remove cowl flap

- Modify exhaust system

- Reposition brake assemblies and lines

- Remove tailwheel assembly

- Wheel pants

- Gear leg fairings

- Paint

- Weight and Balance

- Logbook entry

- Five hour flight test

"Shipwright's Disease" [definition] Items

- Replace Lord mounts

- Replace engine hoses

Progress

- June 28, 2017: Ordered a new engine sump and intake tubes from AERO In Stock in Wasilla, AK.

- June 28, 2017: Chris Tieman said he would send me torque tube attach brackets for me to match drill to my main spar holes.

- June 30, 2017: Received the new Superior sump with a forward injector inlet and intake tubes.

- July 14, 2017: Received torque tube attach brackets from Chris.

- October, 2017: Acquired all parts for the nose gear assembly including strut and wheel fairings.

Planning to order the 'anti-splat' nose strut mod in the future. This is available from: https://antisplataero.com/products/the-nose-job-two

- January 22, 2018: Actually started work on the plane today. Removed cowl, leveled plane and positioned nose gear assembly to determine / confirm adequate prop clearance. For now I have it set such that the bottom of the nose gear attach tube (to be a part of the engine mount) will be flush with the bottom of the fuselage.

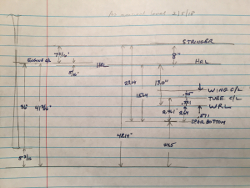

Estimating 5 to 5 1/2" prop clearance at this position. (Not enough). I am planning to try and have between 6.5" and 7" of prop clearance and believe that I can lower the nose gear attach tube about 1.5" to accomodate this. This will require longer main gear legs with my current calculations showing that they will need to be 5.75" longer than the plans for a level sitting attitude.

But I think a nose-up attitude of approximately 2° looks acceptable and will help with the prop clearance while allowing slightly shorter main gear legs.

The math works out that 1° of pitch up occurs from shortening the main gear legs 1".

So the following all affect prop clearance:

1) Vertical positioning of the nose strut (Now planning on the bottom of the attach tube being 1.5" below the fuselage bottom)

2) Nose-up angle for the plane to sit on level ground (Now planning to shoot for +2°), and of course

3) Main gear leg length (Ordered to be 5" longer than plans but tentatively expecting to cut those by 1.25" for a final vertical height of 3.75" longer than the plans)

- February 14, 2018: Ordered main gear legs from Grove Aircraft - estimated delivery time 10-12 weeks. These are a bit long (but with no holes drilled) will enable me to determine the final the axle attachment height.

I decided to go with the vertical leg from the Mustang plans where the axle attaches 5.00" longer than the plans indicate, but may wind up removing about 1.25".

The ordered dimensions:

The 3.25" dimension will be 8.25"

The 4.5" dimension will be 9.5"

The overall 24.15" dimension will be 29.15"

and if necessary, I will cut to length and then drill the axle attach holes. These gear legs will be undrilled at the top but will have a 'gun bore' drill hole throughout them for the brake lines.

- February 22, 2018: Received the following parts from Chris: Rear spar bracket assemblies, cutout materials for the main gear 'torque tube' assemblies, attach brackets, bushings and plates. The plates are pilot drilled. Chris suggested using four AN-8 bolts now vs. the NAS 147 bolts shown on the plans which are very difficult to find.

I plan to do all the aligning, drilling and welding myself.

- April 5, 2018: Received the main gear legs from Grove Aircraft.

- At this point I have all of the materials necessary to proceed with the construction of the main gear assemblies.

- May 4, 2018: Purchased a Lincoln Electric TIG welding unit and will learn how to weld with the assistance of friends in the Anchorage EAA Chapter.

- June 7, 2018: Received the nose gear mounting tube (with bronze bushings installed) from Mustang Aeronautics. I plan to weld this to my existing engine mount.

The Latest:

- June 23, 2018: I did some proficiency flying in the Mustang II when the temperature was almost 100° F and with crosswinds gusting to 18K. It went well, I enjoyed it and two things were realized: I'm "OK" with up to 18 K of crosswind in this plane but I'm rapidly becoming "Not OK" with the thought of doing an extensive modification of a 'perfectly good airplane' - especially in the heat.

I discussed it with a fellow experimental taildragger pilot who had strolled into the hot, humid hangar who fairly emphatically said: "Don't mess up your airplane..." As we each wiped some sweat from our brows I admitted to him that I no longer thought that I had the stamina to put in the numerous hours required to cut into the airplane and do the extensive modification. He succinctly said: "Well don't".

At that moment something 'clicked'. Later that evening I discussed it further with my family - considered the pros and cons - and decided to reverse my decision to modify my Mustang II to a tricycle gear.

Here's to another twenty years of flying my taildragger Mustang II...

I want to express a sincere thanks to John Hack and Dean Olson for sharing their knowledge and wealth of information relating to the conversion.

|